By [Your Name]

October 15, 2025

While wool felt is often celebrated for its crafty charm in handcrafted toys and home decor, a tougher, more technical variant quietly keeps global industries running: industrial wool felt. Engineered for resilience, precision, and versatility, this specialized material has become an indispensable component in manufacturing, automotive, aerospace, and beyond—proving that wool’s natural properties are just as valuable on factory floors as they are in craft studios.

Beyond Craft: The Making of Industrial Wool Felt

Unlike consumer-grade felt, industrial wool felt is crafted with rigorous standards to meet heavy-duty demands. It starts with high-quality wool fibers, often blended with synthetic materials like polyester or nylon to enhance specific traits—such as oil resistance or heat tolerance. The production process emphasizes density and uniformity: fibers are compressed under intense pressure and heat, creating a dense, durable material that retains its shape even under repeated stress.

“Industrial felt isn’t just ‘thicker craft felt’—it’s a engineered solution,” explains Thomas Hale, a materials scientist at a leading industrial textile manufacturer in Ohio. “We tailor every batch to exact specifications: a 3mm-thick felt for automotive gaskets needs different density than a 10mm felt used in printing machines. It’s all about matching the material to the industry’s unique challenges.”

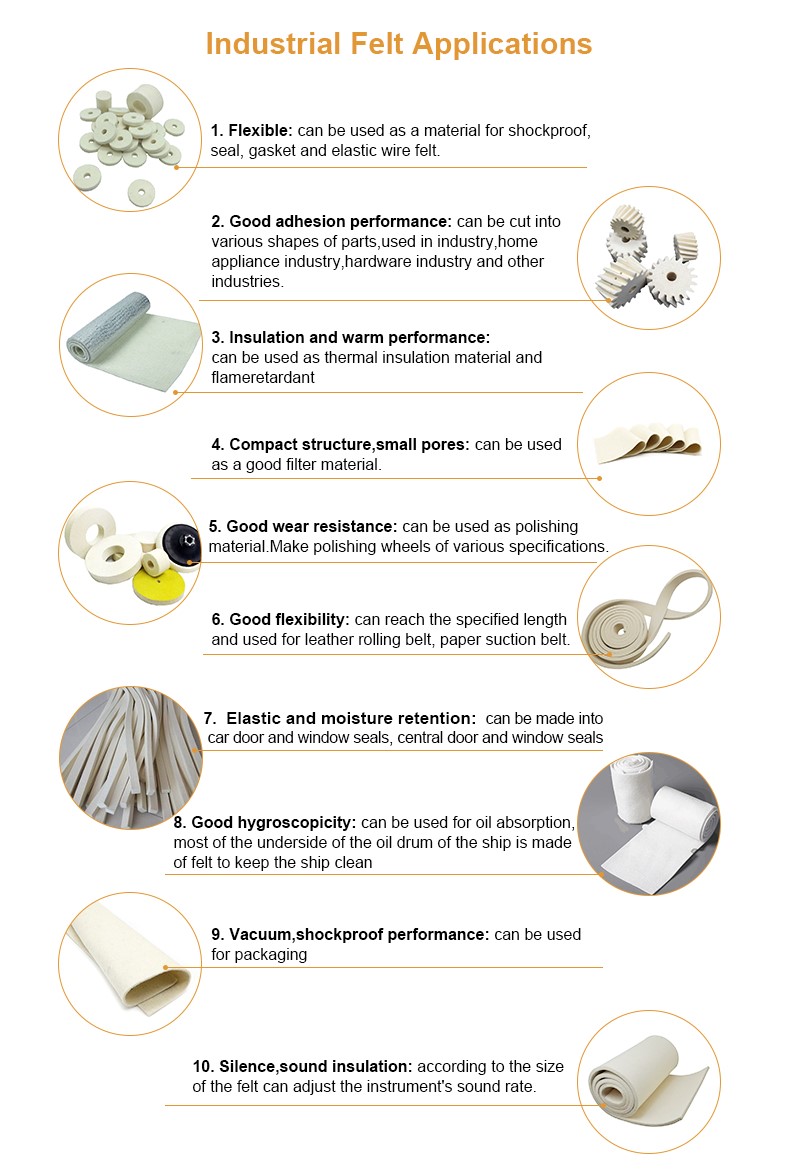

Where Industrial Wool Felt Shines: Key Applications

From automotive assembly lines to aerospace workshops, industrial wool felt plays critical roles that often go unnoticed—until something goes wrong. Here’s how it powers key sectors:

Automotive: Sealing, Soundproofing, and Protection

In cars and trucks, industrial wool felt acts as a multi-tasker. It lines door panels and dashboards to dampen road noise, creates airtight seals around engine components to prevent fluid leaks, and protects delicate wiring from friction damage. “Modern vehicles demand materials that can handle extreme temperatures—from -40°C in winter to 120°C under the hood,” says Elena Marquez, an automotive supply chain expert. “Industrial wool felt outperforms many synthetics here; it doesn’t crack, melt, or lose shape, even after years of use.”

Manufacturing: Precision in Production

In manufacturing plants, industrial wool felt is a staple for precision work. In printing industries, it’s used as a roller cover to ensure even ink distribution on paper and packaging—its absorbent yet firm texture prevents smudges and ensures consistent print quality. In metalworking, thick felt pads protect delicate parts from scratches during machining, while felt wipers remove debris from conveyor belts to keep production lines running smoothly.

Aerospace and Electronics: Small but Mighty

The aerospace industry relies on industrial wool felt for its lightweight yet durable nature. It’s used as a cushioning material in aircraft interiors to reduce vibration, and as a filter in fuel systems to trap tiny particles that could damage engines. In electronics, thin, non-conductive felt sheets insulate sensitive components in smartphones and industrial control panels, preventing short circuits while allowing heat to dissipate.

Textile and Machinery Maintenance

Even the textile industry uses industrial wool felt to maintain its own equipment. Felt brushes clean lint from weaving machines, and felt strips lubricate moving parts by retaining oil—reducing wear and extending the lifespan of expensive machinery. “It’s a full-circle solution,” Hale notes. “The same material that comes from wool fibers helps keep the machines that make other textiles running efficiently.”

Sustainability Meets Industrial Demand

In an era where industries are racing to reduce their environmental footprint, industrial wool felt’s eco-friendly credentials are a major plus. Wool is a renewable resource, and industrial felt is often recyclable at the end of its lifespan—unlike many synthetic alternatives that end up in landfills. Some manufacturers now offer “green” industrial felt, made from 100% recycled wool, catering to brands aiming for sustainable supply chains.

“More clients are asking for eco-friendly options without sacrificing performance,” says Marquez. “A car manufacturer we work with recently switched to recycled industrial felt for their door seals—it meets all their durability standards and helps them cut their carbon footprint. It’s a win-win.”

Innovations Shaping the Future

As industries evolve, so does industrial wool felt. New technologies are expanding its capabilities: nanocoatings add water resistance for outdoor machinery, while carbon fiber blends boost strength for aerospace applications. Meanwhile, digital manufacturing tools allow for precision cutting—creating custom-shaped felt parts that fit seamlessly into complex machinery.

“The future of industrial felt is about customization and innovation,” Hale adds. “We’re seeing demand for felt that can handle 3D printing processes or work in extreme environments, like deep-sea exploration equipment. Wool’s natural adaptability, paired with modern engineering, means this material will keep up with industry’s next big challenges.”

While it may lack the charm of handcrafted felt, industrial wool felt is a silent workhorse that keeps the world’s economies moving. From ensuring your car runs quietly to helping print the packaging of your favorite products, this durable, versatile material proves that wool’s potential extends far beyond the craft table—making it an unsung hero of modern industry.

Tel:+86 13426424820

Tel:+86 10 60211314

.png)